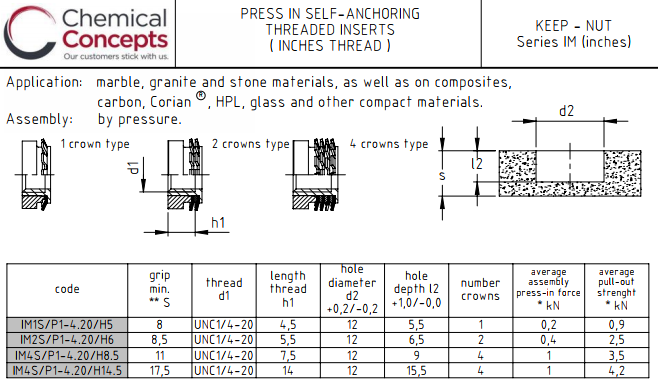

Description

|

Type/Thread/Height |

D1 Thread |

Surface Min. Thickness** |

H1 Thread Depth |

D2 Hole Diameter ⌀ ±0.2 |

L2 Hole Depth +1.0 |

No. of Crowns |

Installation Force kN (lbf) |

Pull-Out Force kN (lbf) |

| IM1S/M6/H5 | M6 | 8.0 mm (.31″) | 4.5 mm (.18″) | 12 mm | 5.5 mm (.22″) | 1 | 0.2 (44.96) | 0.9 (202.33) |

| IM2S/M6/H6 | M6 | 8.5 mm (.34″) | 5.5 mm (.22″) | 12 mm | 6.5 mm (.26″) | 2 | 0.4 (89.92) | 2.5 (562.02) |

| IM4S/M6/H8.5 | M6 | 11.0 mm (.43″) | 7.5 mm (.30″) | 12 mm | 9.0 mm (.36″) | 4 | 1.0 (224.81) | 3.5 (786.83) |

| IM4S/M6/H15 | M6 | 17.5 mm (.69″) | 14.0 mm (.55″) | 12 mm | 15.5 mm (.61″) | 4 | 1.0 (224.81) | 4.2 (944.20) |

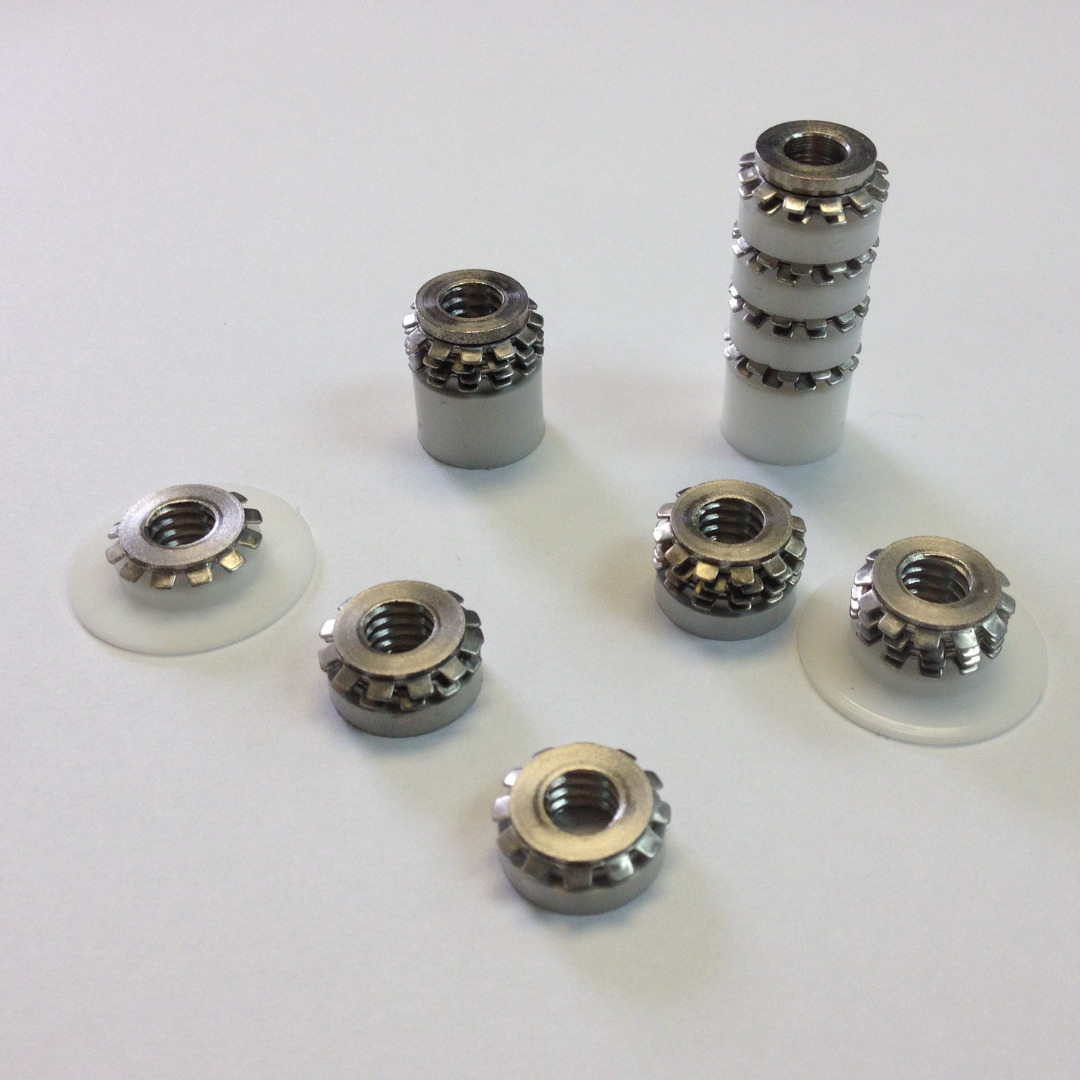

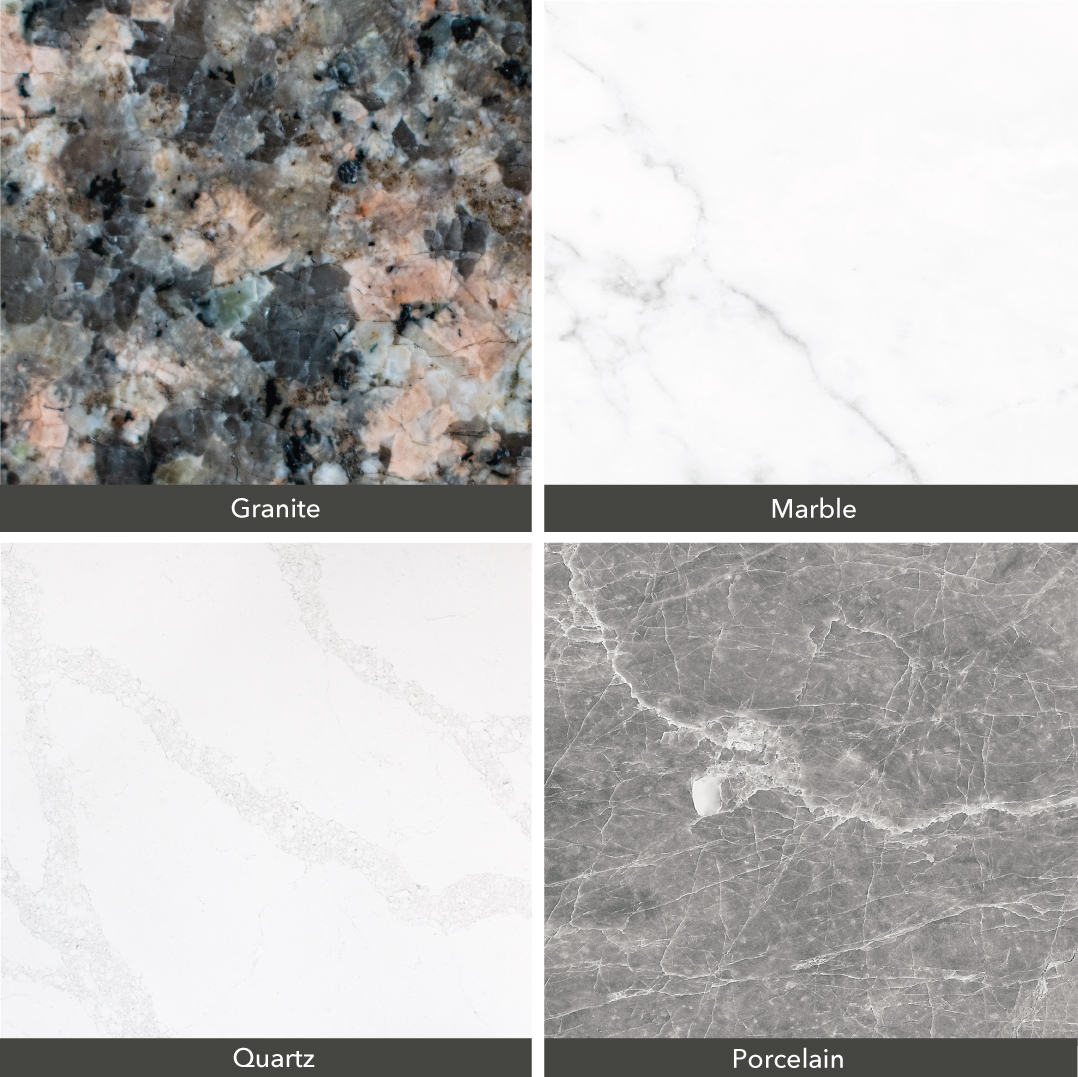

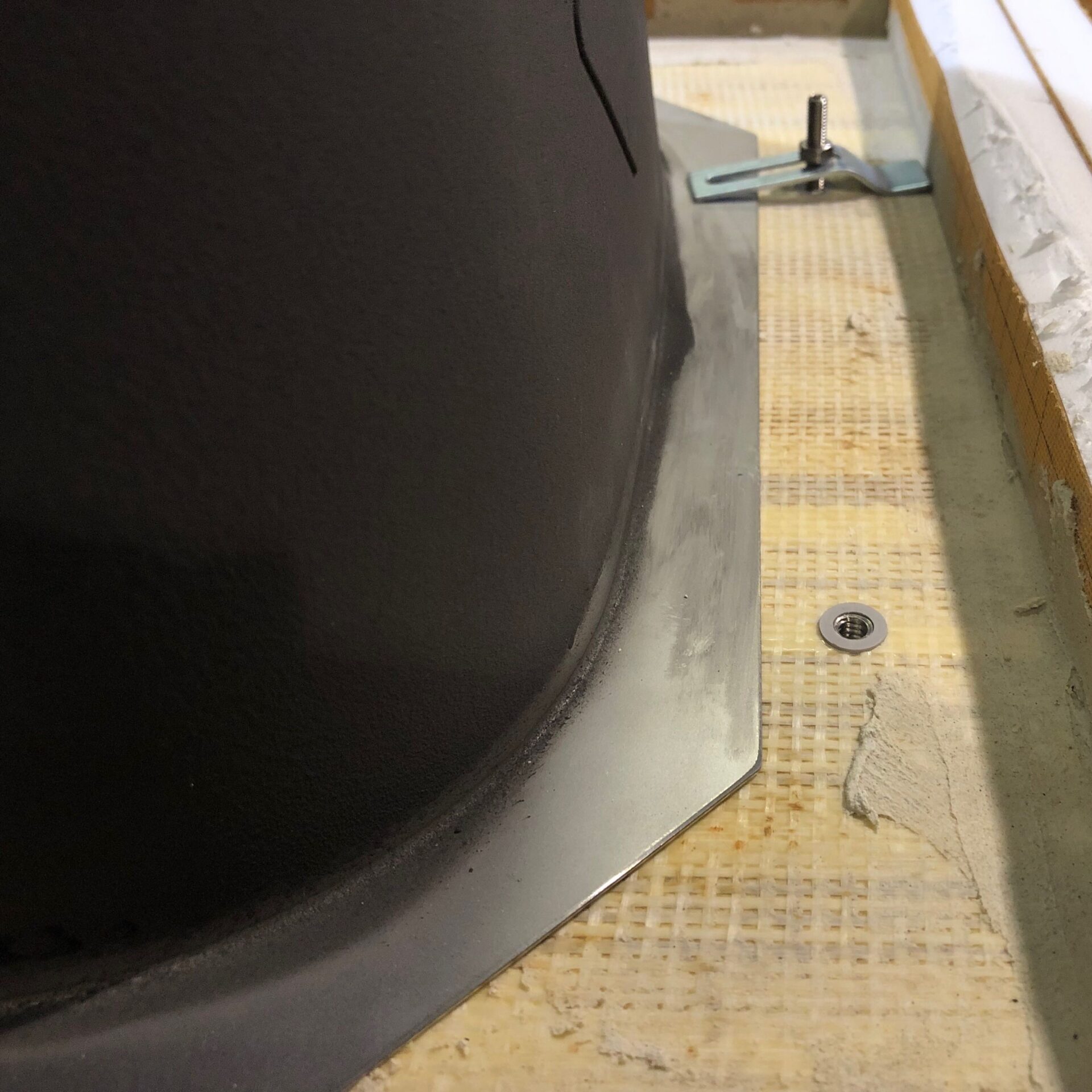

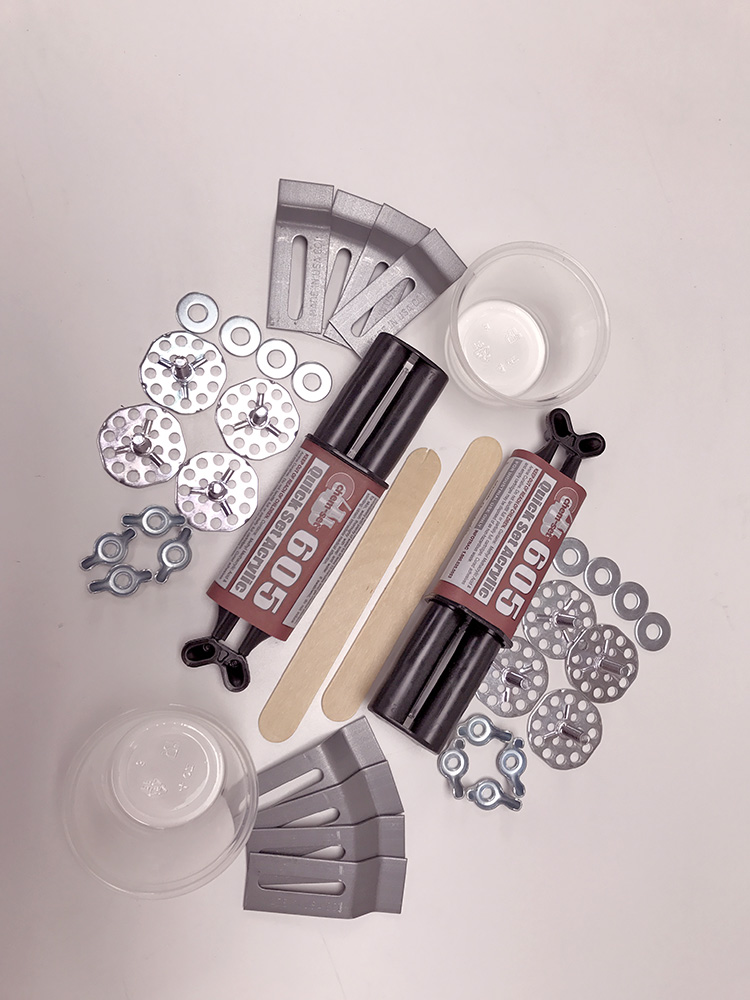

KEEP-NUT™ press-in self-anchoring inserts by Specialinsert is a revolutionary press-in anchor insert commonly used for a number of applications including undermount sink installation, ventilated facades, cladding, and furniture. These small inserts are designed to install into a wide range of surfaces including granite, marble, quartz, solid surface, HPL, glass, fiber cement, and other compact materials.

The solid surface insert’s small size also lends itself to be installed into extremely thin surfaces while also being extremely strong. In addition, the Keep-Nut™ press-in self-anchoring insert is manufactured in stainless steel and it’s made of a threaded bush with a set of elastic crowns and a plastic ring for holding the complete set of parts together.

Advantages:

Advantages:

- Simple hole preparation

- Quick installation

- No need for resins or adhesives

- Radial force is produced only while the insert is under tensile load. The crowns spread the load into the parent material, allowing large loads to be carried

- Thread stops before end of insert, avoiding extraction as a result of the use of an excessively long bolt

Testing Data:

| Material | Type of Keep-Nut | Average pull-out load on a single insert (Kgs.) | Average pull-out load on a single insert (Lbs.) |

|---|---|---|---|

| Granite 20mm | IM4S/M6/H8.5 | 490,0 | 1080.3 |

| Marble 20mm | IM4S/M6/H8.5 | 385,0 | 848.78 |

| Travertine 20mm | IM4S/M6/H8.5 | 225,0 | 496.1 |

| Porcelain Gres 10mm | IM4S/M6/H6 | 150,0 | 330.8 |

| Porcelain Gres 20mm | IM4S/M6/H8.5 | 350,0 | 771.8 |

| Lapitec 12mm | IM4S/M6/H6 | 170,0 | 374.9 |

| HPL 12mm | IM4S/M6/H6 | 541,5 | 1194.0 |

| HPL 8mm | IM4S/M6/H6 | 270,5 | 596.5 |

| Dekton 20mm | IM4S/M6/H6 | 210,0 | 463.1 |

| Corian 12mm | IM4S/M6/H8.5 | 484,5 | 1068.3 |

| Corian 10mm | IM4S/M6/H6 | 290,0 | 650.5 |

| Hi-mac LG12 mm | IM4S/M6/H6 | 240,0 | 529.2 |

| Agglomerate stone 15mm | IM4S/M6/H6 | 305,0 | 672.5 |

| Material | Type of Keep-nut | Mode | Test | Average pull-out load on a single insert kN | Average pull-out load on a single insert (Lbs) |

|---|---|---|---|---|---|

| Black Absolute Granite 30mm | IM4S/P1-4.2/H8.5 | Tensile | ASTM C1354 | 6.35 | 1,427 |

| Black Absolute Granite 30mm | IM4S/P1-4.20/H15 | Tensile | ASTM C1354 | 7.75 | 1,742 |

| Black Absolute Granite 30mm | IM4S/P1-4.2/H8.5 | Shear | ASTM C1354 | 12.64 | 2,841 |

| Black Absolute Granite 30mm | IM4S/P1-4.20/H15 | Shear | ASTM C1354 | 14.78 | 3,322 |

| Caledonia Granite 30mm | IM4S/P1-4.2/H8.5 | Tensile | ASTM C1354 | 2.75 | 617 |

| Caledonia Granite 30mm | IM4S/P1-4.20/H15 | Tensile | ASTM C1354 | 5.62 | 1263 |

| Caledonia Granite 30mm | IM4S/P1-4.2/H8.5 | Shear | ASTM C1354 | 9.26 | 2,081 |

| Caledonia Granite 30mm | IM4S/P1-4.20/H15 | Shear | ASTM C1354 | 13.55 | 3,046 |

| Delicatus Ice Granite 30mm | IM4S/P1-4.2/H8.5 | Tensile | ASTM C1354 | 1.86 | 418 |

| Delicatus Ice Granite 30mm | IM4S/P1-4.20/H15 | Tensile | ASTM C1354 | 3.46 | 778 |

| Delicatus Ice Granite 30mm | IM4S/P1-4.2/H8.5 | Shear | ASTM C1354 | 7.87 | 1,768 |

| Delicatus Ice Granite 30mm | IM4S/P1-4.20/H15 | Shear | ASTM C1354 | 9.74 | 2,188 |

| Sapienstone Porcelain 12mm | IM2S/P1-4.20/H6 | Tensile | ASTM C1354 | 2.73 | 614 |

| Sapienstone Porcelain 12mm | IM2S/P1-4.20/H6 | Shear | ASTM C1354 | 7.43 | 1,670 |

| UHCP 15mm | IM4S/P1-4.20/H8.5 | Tensile | ASTM C1354 | 1.96 | 440 |

| UHCP 15mm | IM4S/P1-4.20/H8.5 | Shear | ASTM C1354 | 6.96 | 1,565 |

| UHCP 19mm | IM4S/P1-4.20/H15 | Tensile | ASTM C1354 | 2.68 | 601 |

| UHCP 19mm | IM4S/P1-4.20/H15 | Shear | ASTM C1354 | 7.08 | 1,591 |

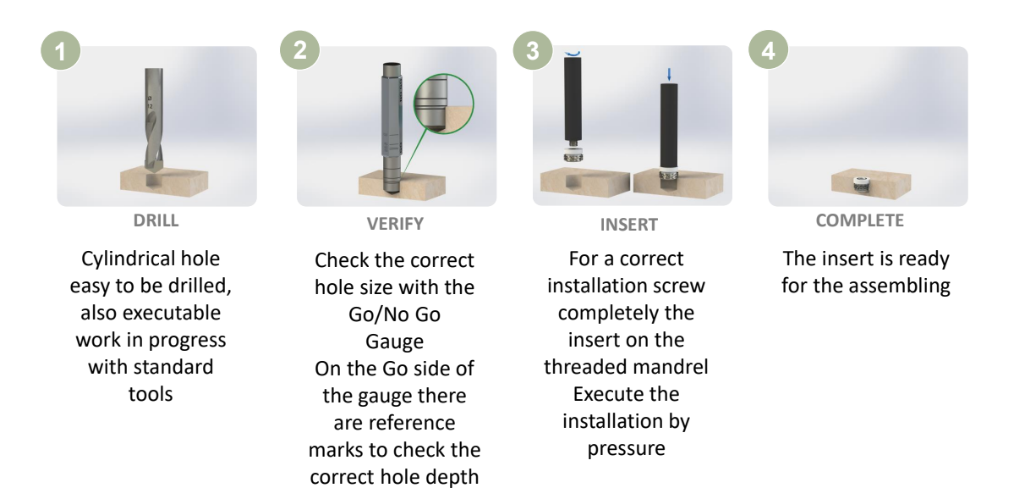

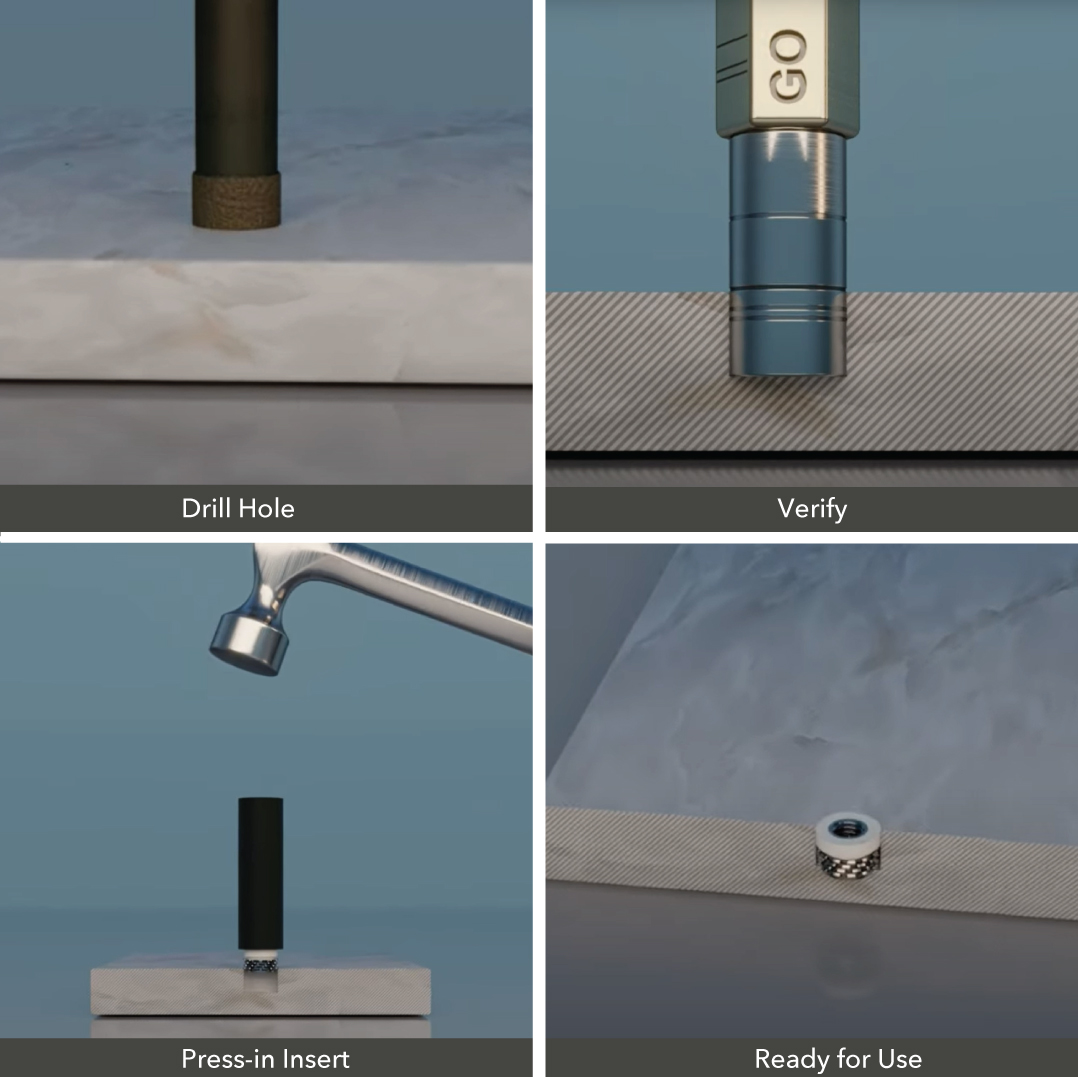

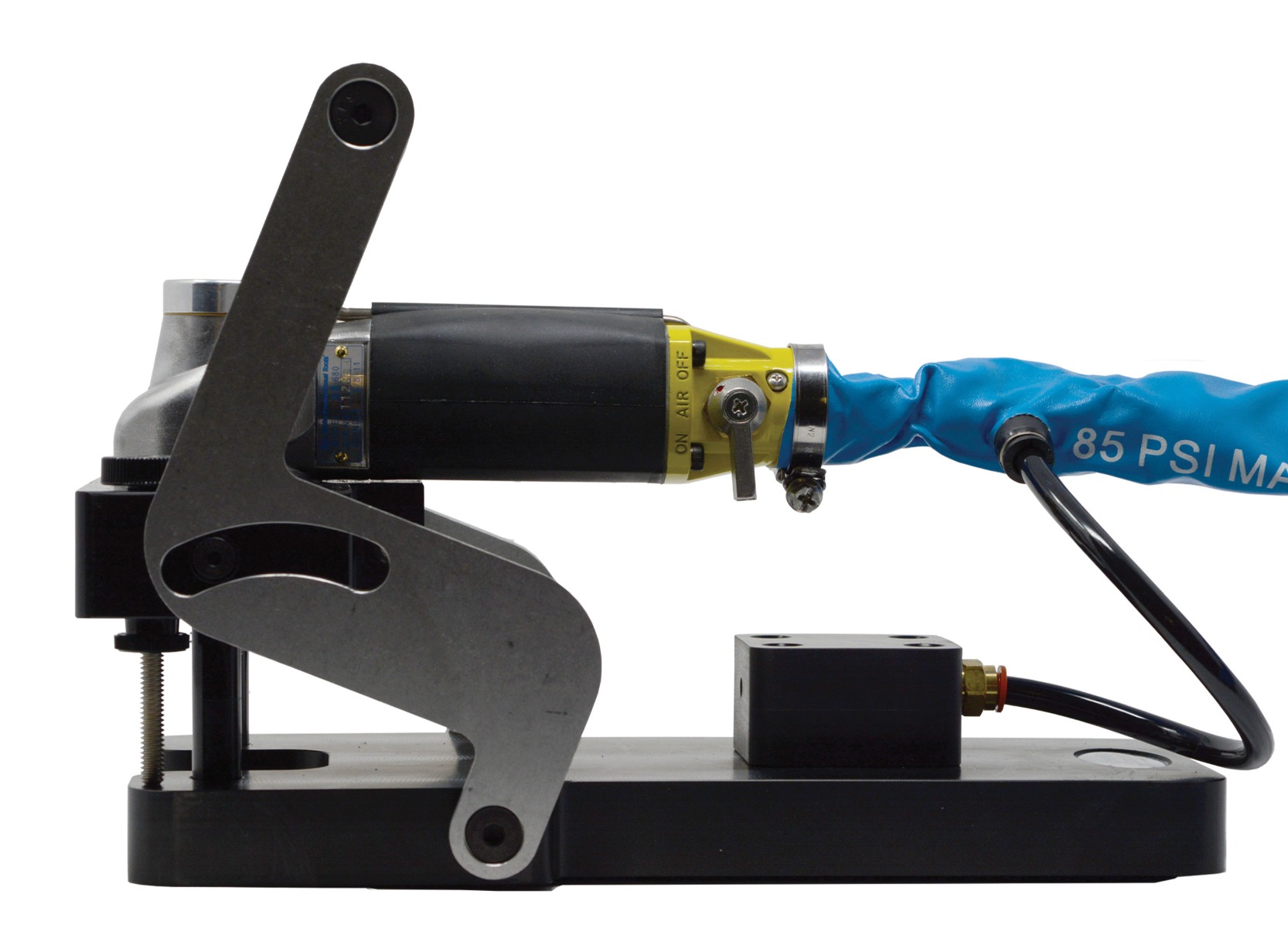

Installation

U.S. Patent No. 10,473,141 (the ‘141 Patent)

Reviews

There are no reviews yet.