Ventilated Facades: Top 5 Advantages & Installation Tips

Ventilated facades are rapidly gaining popularity in the United States, capturing the interest of architects, installers, and property owners alike. Driven by trends in sustainability, energy efficiency, and stricter building regulations, these systems, which are more common in Europe, are expected to become increasingly prevalent in the coming years. In this blog, we explore what ventilated facades are, highlight their key advantages over traditional methods, and discuss options for fixing systems, which are a crucial component contributing to the overall success of a project.

What Is a Ventilated Facade?

A ventilated facade (also known as a rain screen facade) is an exterior cladding system that typically consists of an outer cladding layer separated from the inner wall of the building by an air cavity. This air cavity provides ventilation and temperature regulation and allows any moisture penetrating the outer cladding to evaporate. Here is a quick breakdown of those components.

- Outer cladding: This is the visible layer of the facade. It can be made of various materials, including fiber cement, GFRC, UHPC, natural stone, ceramic, porcelain, ACM or composite panels. The outer cladding is the weather protection layer in a ventilated facade.

- Supporting framework: This metal framework holds the panels and provides the facade with structural integrity.

- Insulation layer: Insulation materials are installed below the outer cladding to enhance energy efficiency and thermal performance.

- Air gap: This is the main feature of a ventilated facade. When installed, there is a gap between the outer cladding and the inner wall that creates a pocket of air. This air gap is critical for ventilation, temperature regulation and moisture management.

Why Are Ventilated Facades Growing in Popularity?

Ventilated facades are becoming an increasingly popular cladding option for many reasons. They offer many advantages that help make buildings more energy-efficient and environmentally friendly.

In cities with stricter building codes, like New York City, where new building code legislation is always being passed, a ventilated facade becomes a very attractive option. Let’s explore some of the advantages, and it will become clearer why this is the case.

Advantages of Ventilated Facades

When compared to traditional methods of cladding or building exteriors, ventilated facades have many clear advantages, including:

- Improved thermal performance: The air gap in a ventilated facade reduces heat transfer between the exterior and interior of the building because they are not in contact. This helps regulate the building’s temperature in both hot and cold seasons.

- Better moisture management: Ventilated facades provide an extra barrier against moisture ingress by preventing water from reaching the building’s structure. If any moisture manages to penetrate the outer facade, it will either drain away through the air cavity or evaporate.

- Greater durability: Ventilated facades extend the lifespan of the building by minimizing exposure to weather elements like wind, rain and UV radiation. This means your building is easier to maintain. A building that’s easier to maintain costs less to maintain.

- Design flexibility: Material options for a ventilated facade system are virtually endless. Many cladding materials, colors and textures are available and can fit just about any architectural design aesthetic.

- Greater sustainability: Ventilated facades contribute to sustainability efforts by improving energy efficiency, which reduces the building’s overall carbon footprint. Also, the material used for the exterior cladding can be sourced from recycled materials, further supporting any green building initiatives.

At the end of the day, all of these improvements over traditional building exteriors lead to a lower cost of ownership. The problem is traditional methods and systems for installing ventilated facades come with some prohibitive disadvantages. Let’s dive into those disadvantages, and then we’ll offer a solution.

Why Traditional Ventilated Facade Installation Methods Fall Short

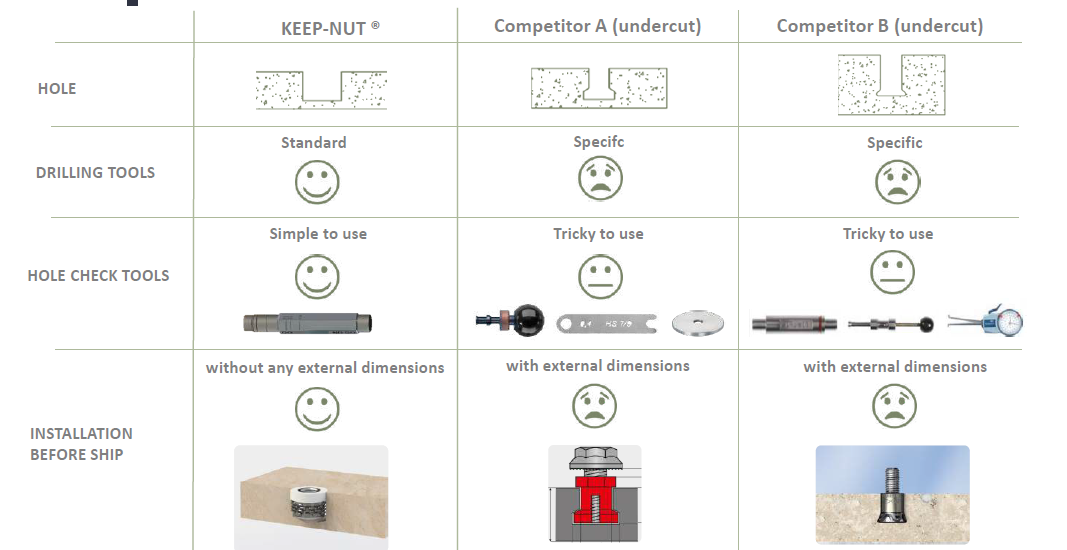

Traditional installation methods, including visible fixing systems, dowel/kerf systems, and undercut anchoring systems, can lead to many problems not only in installing ventilated facades but also in their maintenance and upkeep. Here are some common problems these installation methods come with.

- Aesthetics: Exposed fasteners can compromise the visual appeal of a high-end building project, especially in modern designs where a sleek, seamless and minimal exterior is favored. Visible fixings can also create a problem with water ingress. Because of this, face-fastened materials can be subject to staining, spalling, corrosion or other unsightly conditions around the exposed mechanical fasteners.

- Complex drilling: With undercut methods, a hole is drilled into the material, and then rotated at an angle to make the hole wider at the base. This multi-step drilling method requires specialized equipment, takes up a lot of time to drill and re-drill and is more difficult to automate. It also increases the likelihood of defects and wasted material.

- Modular design: Kerf/dowel systems require each panel to be stacked on the next. This means if there is damage or a panel needs to be replaced lower in the construction, you need to take out all the panels above or around it in the construction. This makes maintenance and upkeep of the ventilated facade challenging, especially if lower panels need to be replaced.

The Keep-Nut System: A Better Way to Install Ventilated Facade

Keep-Nut by Specialinsert is a revolutionary female threaded anchor insert that creates threaded connections on almost all types of panels, including marble, granite, stone and porcelain. It can even work on thin, lightweight panels made of materials like composite, carbon, Corian, HPL, glass and other solid materials.

Keep-Nut is manufactured in stainless steel, and it’s made of a female-threaded bush with a set of elastic stainless steel crowns and a nylon plastic ring.

The Keep-Nut is much simpler than traditional anchoring systems and it comes with some advantages that increase efficiency, making your installations faster and more effective. Here are some of the advantages of Keep-Nut over traditional methods.

- Simpler drilling: Unlike undercut anchoring methods, with Keep-Nut, you only need to drill one STRAIGHT hole into the hanging substrate using standard tools. This reduces machine time, allowing you to use less complex (and less expensive) equipment such as our KDM115 Drill Machine or CNC Router..

- No Blowouts: Keep-Nut are also manufactured with a stop thread which means you cannot over torque your bolts or posts through the Keep-Nut insert which can result in blow-out. This leads to less material waste. It also allows builders to use thinner materials without fear of defects. This lowers material costs and allows for sleeker designs if aesthetics are important in the project.

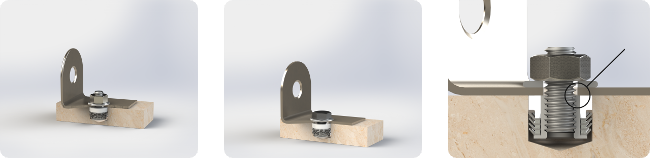

- Easier maintenance: With Keep-Nut, panels are inserted directly into the facade. There’s no need for panel overlap. That means if a panel needs to be replaced anywhere in the construction, you only need to detach and replace one broken panel.

The Keep-Nut Ventilated Facade Installation Process

Installing Keep-Nut into your cladding material is simple. The video outlines the full process. Plus, we have step-by-step instructions outlined below.

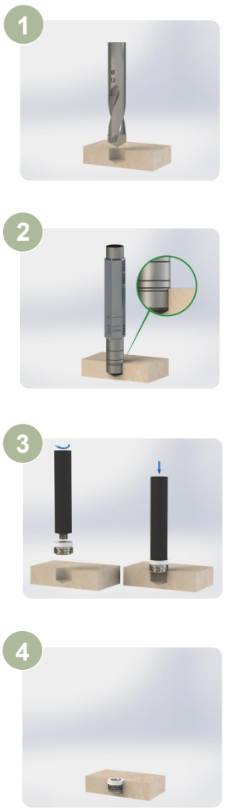

Step 1: Drill the Hole

Keep-Nut is unique in that it doesn’t require undercutting or any special drill bits. All you need to do is drill the desired size hole into your cladding material with drilling equipment you already have.

Step 2: Verify Hole Size

Keep-Nut also comes with a simple-to-use “Go/No-Go” gauge. On the “Go” side of the gauge, there are reference marks that make it easy to check for the correct hole depth.

Step 3: Insert Keep-Nut

Now, all you need to do is insert the Keep-Nut into the panel. Screw the insert completely onto the threaded mandrel to ensure correct installation. Then press down. Keep-Nut will be fully installed into your panel, and you can unthread the insert to use on the next insert.

Step 4: Install Your Panel

With the Keep-Nut insert in your panel, it’s now ready for assembly on your ventilated facade.

When it comes to installing your panel, Keep-Nut allows for internal assembly without any external dimensions, making panels easier to store and handle while also allowing for a totally flush installation.

Keep-Nut also works on a wide range of materials. No matter what material you’re using for cladding, the odds are that Keep-Nut will work.

Conclusion: Embrace Simple, Undercut-Free Ventilate Facade Installation Technology

As ventilated facades, rain screens and wall cladding grow in popularity, it’s important to arm your business with the right technology to install these new forms of cladding. While there are many options on the market, the Keep-Nut by SpecialInsert is the most efficient way to ensure ventilated facade projects are done efficiently and well, so your clients can experience the benefits and reduced cost of ownership of a ventilated facade.

Portfolio

Here are some facade projects around the world fixed with Keep-Nut:

At Chemical Concepts, we’ve been on the leading edge of innovative building processes and installation methods. Have questions about ventilated facade installation? Get in touch with us.