Description

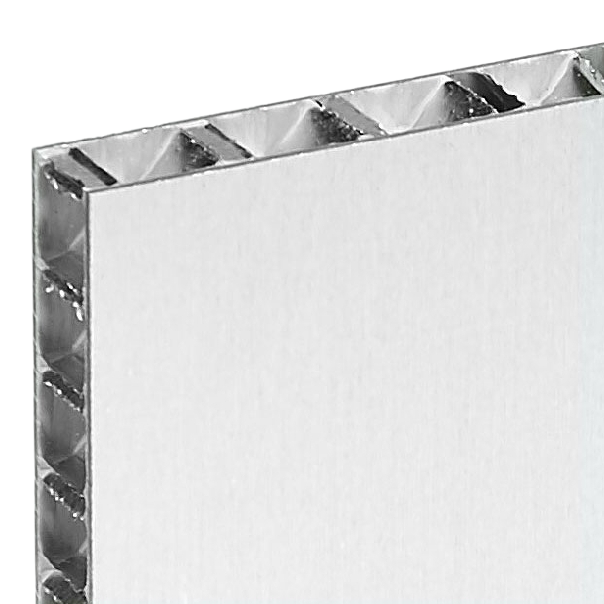

Compocel AL is an advanced aluminum sandwich panel featuring an aluminum honeycomb core bonded to two aluminum skins. This 95% aluminum construction offers exceptional mechanical properties, making it ideal for projects requiring high rigidity and minimal weight.

Benefits of Compocel AL:

- Lightweight: Reduce overall product weight, saving material and transport costs.

- High Strength: Achieve superior mechanical properties, enhancing product durability.

- Pre-primed: Ready for adhesion, saving time and effort on surface preparation.

- Fire Resistant: Meet fire safety standards for various applications.

- Easy Handling: Facilitate installation and reduce labor costs.

- Eco-Friendly: Lower CO2 emissions with reduced material usage and transport needs.

Applications:

- Reinforcing Marble and Stone: Reduce weight and increase strength for marble, semi-precious stones, and other materials.

- Construction: Ideal for projects requiring lightweight, high-strength panels.

- Transportation: Achieve weight reduction for improved fuel efficiency.

- Aerospace: Meet stringent performance requirements for aerospace applications.

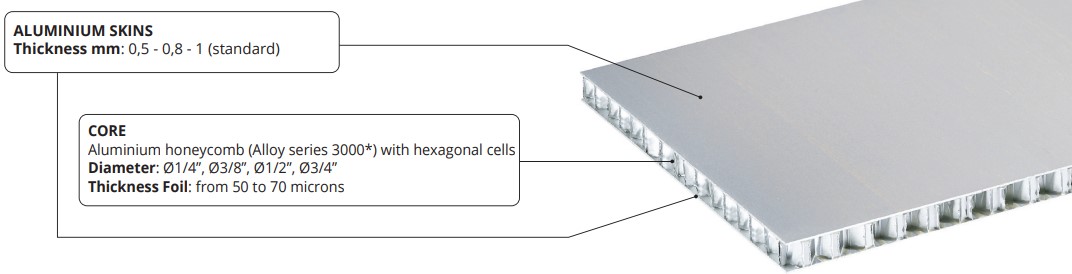

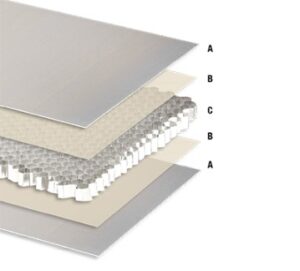

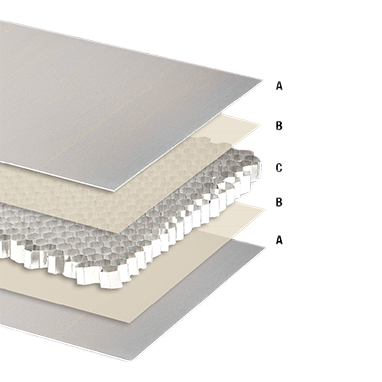

Structure:

|

A: Aluminum Skins

B: Structural Adhesive C: Core in aluminum honeycomb

|

Technical Characteristics:

| Total Thickness of Panel | 1/4″ (6.4mm) 1/2″ (12.7mm) 3/4″ (19mm) 1″ (25mm) Contact for Custom Thickness |

| Panel Size | 5′ x 10′ Contact for Custom Panel Size |

| Skin Thickness | 0.03″ (0.8mm) |

| Aluminum Skin | 3000 Series |

| Honeycomb Aluminum Alloy | 3000 Series |

| Diameter of Honeycomb | Ø3/8″ (9mm) |

See TDS for more information

Processing Methods:

- Cutting, sawing, drilling, and shaping: CEL is able to produce customized shapes, holes and processing, according to specs

- Joining and Fixing: some projects require an anchoring system to fasten panels to other surfaces.

- Options include:

- 1) Panels attached to each other by visible or blind rivets and screws

- 2) Fixing with self-tapping screws (sealing washers) in aluminum or stainless steel

- 3) Fastening with drilling screws

- Options include:

Surface Finishing:

Compocel AL finishes are selected carefully for indoor and outdoor applications; high quality polymeric paint such as PVDF and FEVE are available on request. CEL offers various surface treatments, in order to resist to heat peaks and temperatures. Overall orders are necessary in case customer needs specific finishes or colors; in this way all aluminum sheets are produced in a batch without any minimal pigment variation.

- Oxidation: Aluminum sheets can be covered with an anodic oxidation coating. This process increases corrosion and wear resistance, improving adhesion for paint, primers and glues.

- Painting: Aluminum panels can be finished with powder or liquid paints, combining aesthetics with environmental needs; Antibacterial and dissipating paints for indoor and outdoor are available on request.

- Serigraphy: High resolution and durable printing are possible thanks to the use of UV resistant inks.

Edging:

Contact Us About Custom Edging Finishs!

- Flat edging (or applied edge)

Extrusions in different materials can be used: aluminium, laminate, PVC, ABS and even in a colour coordinated with that of the outer skin of the panel. They are bonded using a suitable, tear-resistant glue - T-profile edging

By means of a T-profile, applied with suitable glue after milling the core of the panel. The combination of milling and glue gives greater hold and rigidity on the outer perimeter. - Edging with a C profile

After milling the core of the panel, a C profile is applied with suitable glue. - Edging by folding a metal sheet back on itself

The outer skin, which is slightly scored, is folded over and glued perfectly until it covers the thickness of the panel.

Reviews

There are no reviews yet.