Product Spotlight: Lord’s 810/20 LRT Acrylic

If you’re on the hunt for a strong, flexible acrylic with LRT properties, Lord’s relatively new product, the 810/20 Acrylic Adhesive, could be the perfect fit for you. Leveraged with applications from vehicle part assembly to architectural cladding, this product from one the world’s leaders in adhesives offers a strong, flexible and non-sagging option for bonding metal and plastic surfaces.

LRT (Low Read Through) and why it’s important

For automotive OEM’s especially, “read through” has become an increasing problem in bonding materials since thinner-gauge, composite substrates are becoming more popular. The thinner composites, as opposed to the bulkier steel components of the past, allow for good cost savings and better fuel economy for manufacturers in the transportation industry.

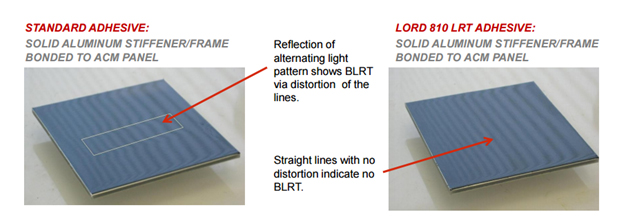

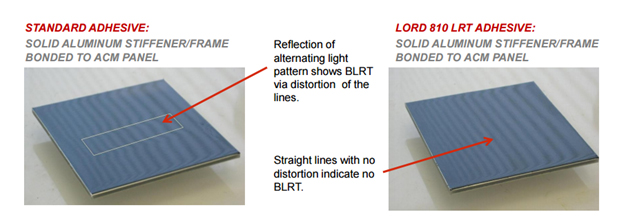

Read through essentially is the surface distortion of thinner-gauge materials, like metal or composite, due to adhesive application. Seeing the effects of an adhesive through the substrate is not ideal when the appearance of the metal finish is important, like it is with automotive OEM’s.

The Solution: Lord’s LRT 810 Acrylic offers a reprieve from the messy bleed through that can leave metal or composite surfaces looking subject. With standard adhesives, visibly distorted patterns and lines can become an eye sore on metal panels, but with Lord’s 810 LRT (see below) lines remain uniform, intact, and much more presentable.

Benefits

- Excellent curing time – Lord’s 810 LRT only requires about 20-30 minutes of handling time! Compart this to sometime typical curing timetable of up to seven days for other Low-Read- Through Adhesives.

- Great for bonding thin-gauge metal-to-metal and metal-to-composite/plastics

- The perfect choice for fascia bonding where appearance and aesthetic perfection is a priority, like vehicle panels, sign assembly, and more.

- Good environmental resistance – 810/20 can withstand the elements, UV exposure, moisture, oils, acids and more.

Characteristics

- Fast curing time, even in low temperatures

- A structural adhesives with low shrinkage, good flexibility and low exotherm

- Two component formula (2:1)

- Paired with Accelerator 20, precise bond lines are a cinch (glass bead filled formula)

- Requires very little to no substrate prep

- Superior peel strength

- No sagging or slumping after application

- Six month shelf life when stored below 77 degrees F in original container

How to use it

- Prepare the surface by removing any and all loose contamination or grease

- Mix the 810 adhesive with the Accelerator 20 at a 2:1 ratio. (A good indicator of a thorough mix is even color distribution.

- Apply the mixture to the bond surfaces

- Fixture the components. Handling strength is achieved in just 25 minutes!

- Curing is 90% complete in 30 minutes at room temperature. The cure rate can be increased by applying modest heat. (greater than 150 degrees F – 66 degrees C)

Questions?

We’d be glad to field your questions, provide advice, or even walk you through the process. You can order Lord’s 810/20 through our website, and always feel free to give us a call (800-220-1966) or email us!