Product Spotlight: Keep-Nut Drilling Machine

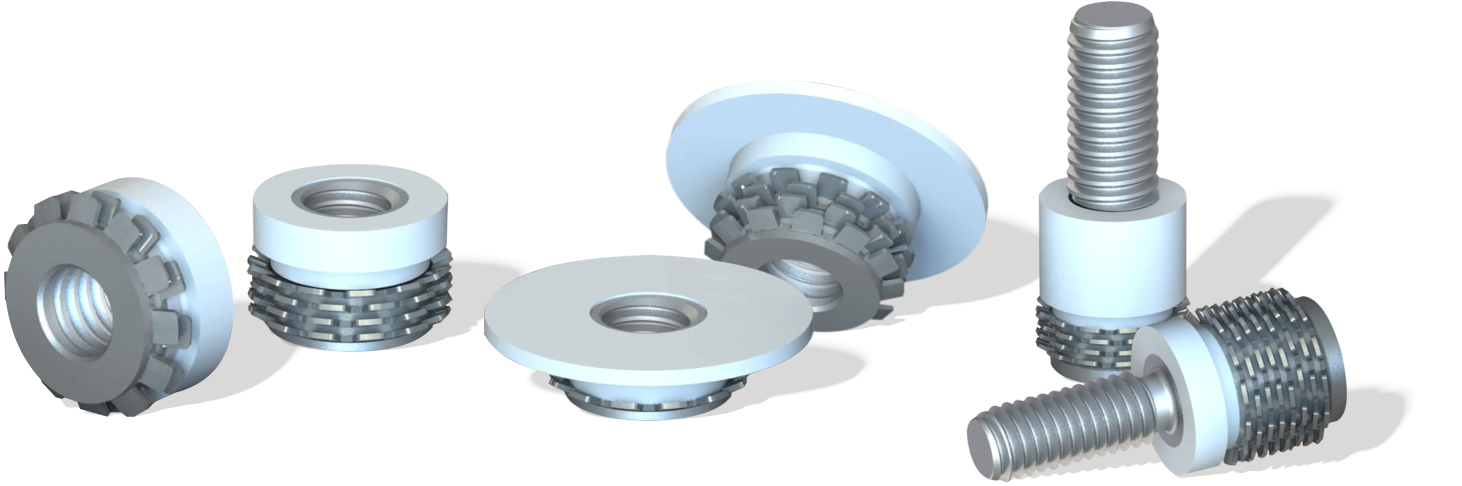

Keep-Nut® is a press-in threaded insert that mechanically anchors to provide permanent threads in panels or countertops made of marble, granite, composites, carbon, Corian®, HPL, glass and others solid surface materials.

Keep-Nut® is a press-in threaded insert that mechanically anchors to provide permanent threads in panels or countertops made of marble, granite, composites, carbon, Corian®, HPL, glass and others solid surface materials.

The Keep-Nut insert is specifically developed to fasten ventilated façades, wall-coverings, décor, furniture, under-mount sinks, as well as a variety of other applications.

The Keep-Nut is manufactured in stainless steel and consists of a threaded bush, a set of toothed spring washers (crowns), and a plastic ring holding the parts together. Available in different lengths to fit several different panel thicknesses, Keep-Nut can be installed quickly by drilling the material to the correct hole diameter and pressing in the insert.

Keep-Nut inserts have several advantages. The preparation needed is just a cylindrical hole drilled by CNC or a Grinder/Polisher. In addition, assembly by pressure is quick and easy and does not require use of any adhesives.

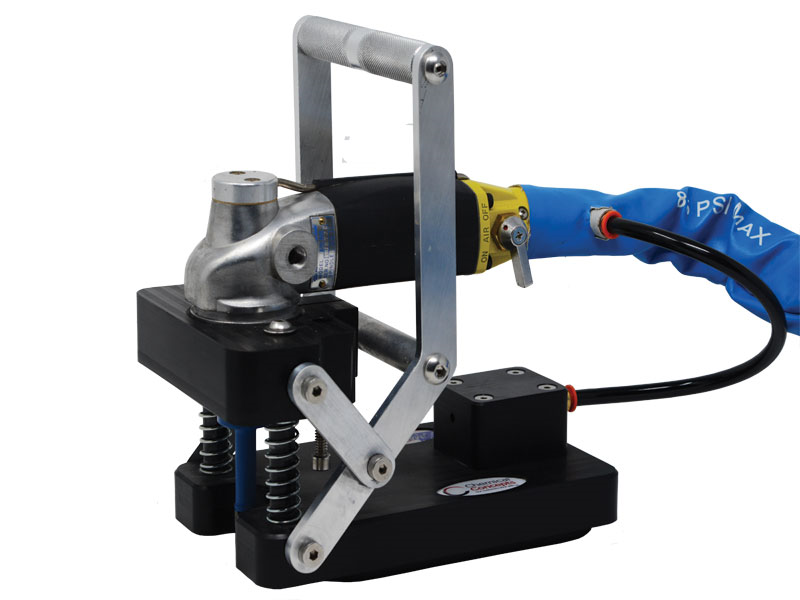

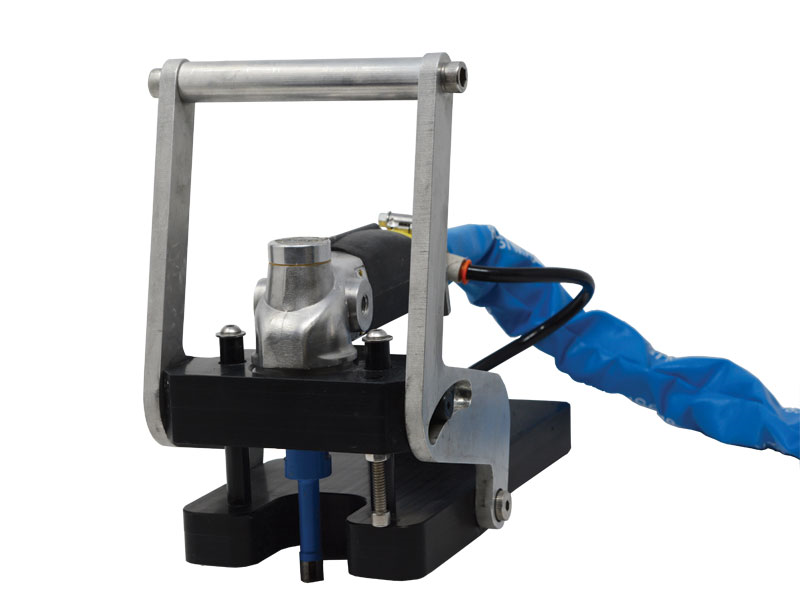

The KDM110 Keep-nut Drilling Machine from Chemical Concepts, is a lightweight, precision tool for drilling panels and countertops. This machine will enable any operator to repeatedly and efficiently drill holes with the correct dimensions for use with the Keep-nut anchoring system. Using an array of compatible bits, the machine can prepare holes in a variety of hard surfaces including granite, marble engineered stone, UHPC, porcelain, Dekton®, glass, and composites. The vacuum foot allows secure attachment to rough surfaces including unpolished granite and textured ceramics. This water-cooled, pneumatic machine requires only a single air line and a water feed to operate. Use with thin-wall core bits to drill faucet holes in record time without a CNC.

The KDM110 Keep-nut Drilling Machine from Chemical Concepts, is a lightweight, precision tool for drilling panels and countertops. This machine will enable any operator to repeatedly and efficiently drill holes with the correct dimensions for use with the Keep-nut anchoring system. Using an array of compatible bits, the machine can prepare holes in a variety of hard surfaces including granite, marble engineered stone, UHPC, porcelain, Dekton®, glass, and composites. The vacuum foot allows secure attachment to rough surfaces including unpolished granite and textured ceramics. This water-cooled, pneumatic machine requires only a single air line and a water feed to operate. Use with thin-wall core bits to drill faucet holes in record time without a CNC.

- Fast, efficient drilling on hard surfaces

- Lightweight and easy to operate

- Vacuum-foot for secure attachment to rough or even vertical surfaces

- Water cooled and air-operated

- Built in depth stop for precise, repeatable results