Product Spotlight: Chem-Set 605 Quick Set Acrylic Adhesive

Reading Time: 3 minutes

Advantages of Using Acrylics

Acrylics offer durable bonds that attain its maximum strength in a fraction of the time it takes other adhesives; they’re just as strong if not stronger than the typical epoxy. Acrylics also require little surface preparation prior to an application of a given substrate, and are known to achieve a strong bond with difficult surfaces like slick or oiled metals. They have the best adhesion on metal, plastic and ceramic substrates. Acrylics are formulated with two parts, a resin and an accelerant, that are mixed just before they are dispensed to promote a quick and effective cure.

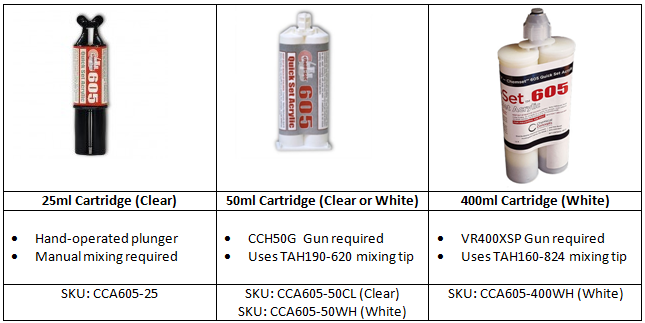

This easy-to-use, two-part adhesive gel is the perfect match for non-porous substrates like engineered stone. It’s also an effective means of adhering plastics, metals and many other substrates. The 50ml cartridge (as depicted above) is a 1:1 ratio of the aforementioned resin and accelerant, which negates the need for tedious ratio measurement for an application.

Where should it be used, and how?

We recommend this product for sink under-mounting projects (that use metal sink fasteners) or similar structural applications, which require adhesion to non-porous substrates like porcelain or stone- surfaces commonly found in kitchen and bath installations. It’s also commonly used in the following industries and applications:

- Engineered Stone

- Magnet and speaker assembly

- PVC, fiber glass, ABS, steel, aluminum, wood, concrete, & ceramic

- Thermoformed plastic

- Surfaces exposed to external elements (i.e. weathering, solvents)

Other Product Information

- Operating Temperature range – 67 degrees F – 250 degrees F +

- Open Time- Three minutes (at 72 degrees F – 22 degrees C)

- Assembly Time – Six Minutes

- Fixture Time- 15 Minutes

- Functional Time – 45 minutes to an hour

- Impact resistance – 22 lbs per inch

- Peel Strength – 35-40 psi

- Tensile/Shear Strength – 1,300 – 3,000 psi (strongest when bonded to grit-blasted steel)

Benefits of Using 605 Acrylic Adhesive

- Convenient 1:1 mix ratio

- Cures at room temperature

- Bonds dissimilar plastics

- Non-sagging formula

- Minimal surface preparation is required

- High resistance to hydrocarbon based fuels (jet fuel, gasoline, oil, hydraulic fluid, etc).

The Process

Dispensing Chem-Set 605 Acrylic Adhesive can either be done manually or with automated equipment. The acrylic should be directly applied to the surface at a ratio of 1:1. The two surfaces being adhered together should be mated within the 3 minutes of dispensing to assure full bond strength. All part positioning and placement should be completed by the six minute mark. Once both application and fixture are out of the way, simply allow 15 minutes to set before handling.

Related products/accessories

The Chem-Set 605 Quick Set Acrylic Adhesive is recommended for use with any of the other Chem-Set products below in mounting or attaching sinks. These accessories, along with the acrylic itself, make for a total package in the area of sink installation (referenced in the picture below).

The Chem-Set 605 Quick Set Acrylic Adhesive is recommended for use with any of the other Chem-Set products below in mounting or attaching sinks. These accessories, along with the acrylic itself, make for a total package in the area of sink installation (referenced in the picture below).

The completed assembly of a single sink under-mount: a no-drill bonding fastener, a “Z” stamped sinks clip, and wing-nut).

- Chem-Set 735-8 Sink Mount Kit

- Chem-Set 732G “Z” Shaped Stamped Metal Sink Clips

- Chem-Set No Drill Bonding Fasteners

- Static Mixer for 50ml Cartridges

- Static Mixer for 400ml Cartridges

- Chem-Set PAK-50 gun for 50ml Cartridges

- VR200XSP Gun for 400ml Cartridges

Contact our Sales team for more info!

sales@chemical-concepts.com – 800.220.1966