Description

PERMABOND TA4610 is a 2-part, 1:1 toughened acrylic adhesive. It has been developed to bond low-surface energy plastics such as polypropylene and polyethylene with no primer or surface treatment required. It can also be used to bond a wide variety of other materials such as metals and composite materials and is ideal for bonding dissimilar surfaces.

See our blog about choosing a polyolefin bonding adhesive

Features & Benefits

- Adhesion to a wide variety of substrates

- Full cure at room temperature

- Bonds polyolefins and low-energy plastics such as HDPE, PP, PE, PTFE

- No primer or surface prep required

- Good impact strength

- Good chemical resistance

Common Substrates: Polypropylene, Polyethylene, HDPE, PTFE, Mild Steel, Stainless Steel, Aluminum, Carbon Fiber, FRP, GRP, ABS, Polycarbonate, PVC, EPDM, PA6, PET-G, PE-P

Physical Properties of Uncured Adhesive

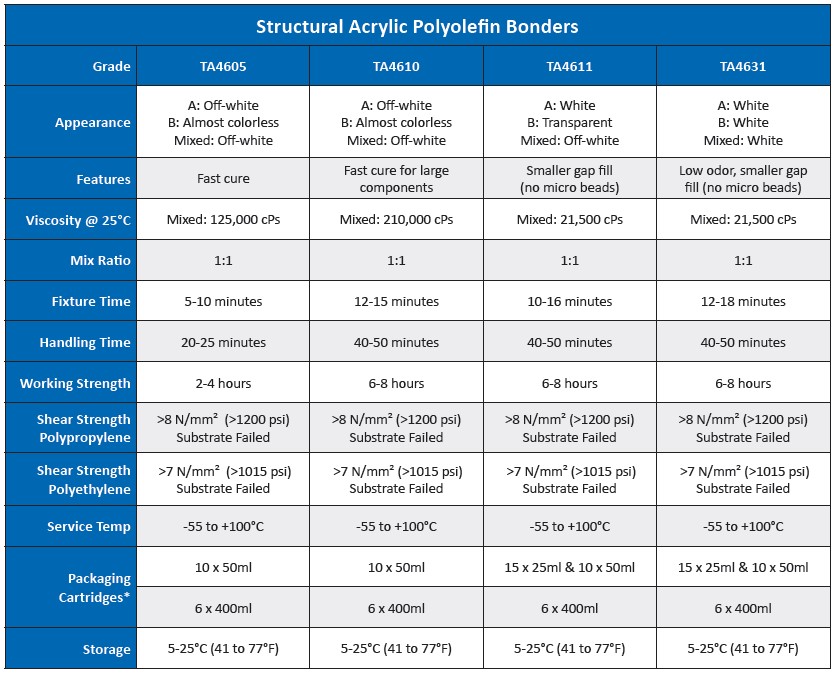

| TA4610 A | TA4610 B | |

| Chemical Composition | Methacrylate | Methacrylate |

| Color | Off-white | Almost colorless |

| Mixed Color | Off-white | |

| Viscosity @ 25°C | 200,000 – 500,000 mPa.s (cP) Thixo paste | 20,000-30,000 mPa.s (cP) |

| Specific gravity | 1 | 1 |

Typical Curing Properties

| Ratio to Use | 1:1 |

| Maximum gap fill

(NB: Contains microparticles to control gap) |

1 mm (0.04 in) |

| Pot life (2g+2g) @23°C | 5-8 minutes |

| Fixture time

(0.1 N/mm² shear strength is achieved) @23°C |

12-15 minutes |

| Handling time

(0.3 N/mm² shear strength is achieved) @23°C |

40-50 minutes |

| Working strength @23°C | 6-8 hours |

| Full cure @23°C | 24-36 hours |

Comparable to: 3M DP8005, DP 8010, and DP-8010

Reviews

There are no reviews yet.