NEW – Siasponge Series Pads, Discs, and Blocks – Part II

In Part I of our blog covering the new Siasponge line of abrasives, we detailed some of the clear advantages of this new line of products. These include its green, sustainable features, its advanced foam technology, which supports an even and optimized application and final result, and its convenient color coded grit format, which is highly resistant to fading over time, keeping its color even under the harshest of conditions.

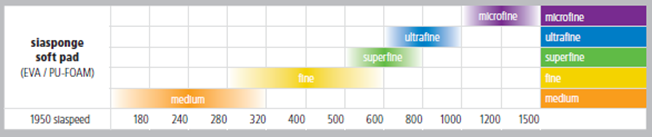

See the chart below comparing the grit ranges of each Siasponge Soft Pad color type, compared to the Siaspeed 1950 grit ranges.

In this blog, we’re going to continue to harp on the benefits of this great product series, but also highlight a few of the individual products and where and how you might use them.

Pressure Distribution

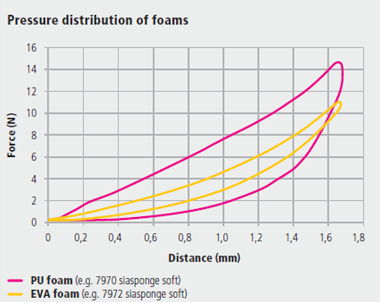

B ecause we’ll continue to mention both PU and EVA type foams throughout this blog series, it’s prudent to cover the difference between the two in relation to pressure distribution. The below chart maps out the pressure distribution of both the 7970 PU foam and the 7972 EVA foam. As you can see, more force is distributed by way of the 7970 wet sanding sponge in comparison to the 7972 dry sander. It’s of importance too that the larger the area between the curves, the more local energy it is that’s being absorbed and transmitted. So the harder, more pressure-effective PU 7970 would be more useful with wet applications that require a bit more power, whereas the lower profile EVA 7972 does just fine with dry-only environments.

ecause we’ll continue to mention both PU and EVA type foams throughout this blog series, it’s prudent to cover the difference between the two in relation to pressure distribution. The below chart maps out the pressure distribution of both the 7970 PU foam and the 7972 EVA foam. As you can see, more force is distributed by way of the 7970 wet sanding sponge in comparison to the 7972 dry sander. It’s of importance too that the larger the area between the curves, the more local energy it is that’s being absorbed and transmitted. So the harder, more pressure-effective PU 7970 would be more useful with wet applications that require a bit more power, whereas the lower profile EVA 7972 does just fine with dry-only environments.

970 & 7972 Pads & Discs

The Siasponge 7970 Soft Pad is a flexible, single-sided abrasive sponge comprised of aluminum oxide. It’s best used for wet sanding applications, as it’s made from PU foam, as opposed to EVA foam. PU foams have much better capability in dry or damp situations, whereas EVA foams, like the 7972 sponge for instance, are limited to dry sanding applications.

In addition to being capable in wet environments, the 7970 doubles as the hard-to-reach sponge. It excels in tricky areas like radiator grills, door handle depressions, and bumpers.

The 7972 variety pads are best used for dry sanding. Some common applications for the 7972 are the sanding of plastics prior to applying primer, fine sanding of filler, keying of primer coats, and intermediate lacquer sanding. The EVA foam material with which the 7972 is made is highly flexible, resistant to tearing, and is well suited for machine-based deployments.

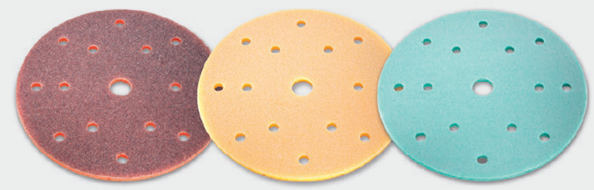

The 7972 Soft Disc, unlike the 7972 Soft Pad, is capable of sanding wet or dry areas. These discs (pictured above) work well for the sanding of composite parts, the matting of varnishes, and the fine sanding of body filler. This amphibious disc can also be placed directly onto machines without the need for an intermediate pad.

In Part III of our blog series on the Siasponge line of abrasives we’ll cover the remaining Siasponge products, including the 7983 pads and discs and the 7990 and 7991 blocks. Stay tuned!

sales@chemical-concepts.com – 800.220.1966