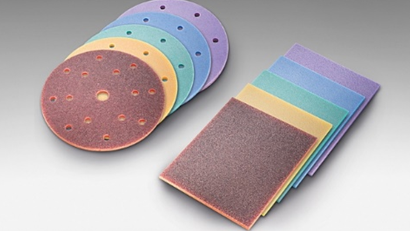

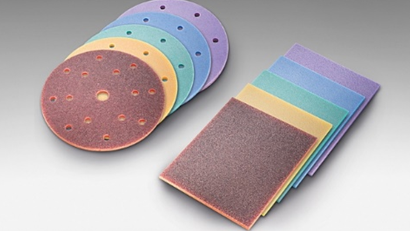

NEW – Siasponge Series Pads, Discs, and Blocks – Part I

It’s not often that we talk about abrasives, or the driving force that grinds, shapes, and prepares a surface for adhesion, but when we do the worldwide leader in this area, Sia Abrasives, is somewhere in the picture. At Chemical Concepts, we carry the gamut of Sia’s abrasives products, and we’re glad to announce too that this includes their new Siasponge line of abrasives.

Siasponge Series Advantages

The Siasponge series is perhaps set apart first and foremost by its sustainability, safety, and user-friendly design. Each pad, disc, or block is created with solvent-free binder resins, making them extremely safe both for the environment and the contractor handling them to abrade or key a surface. In addition, these innovative abrasive sponges are comprised to be free of nasty odors and of possibly hazardous vapors.

More Advantages

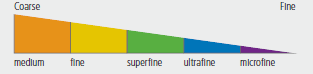

- Due to its color coded system, mixing up your sanding grits will be a thing of the past

- Very versatile – works well with plastics, composites, varnishes, paints, outdated lacquers, and primers

- Flexible yet resistant to folding and bending

- Uniform scratch pattern as a result of excellent grain consistency

- Resistant to discoloration on the grit side

- Resistant to bulging corners

- No annoying and unpleasant acrid solvent odors

Foam Technology

Sia’s state-of-the-art foam technology offers, above all else, an optimized and even distribution of the pressure being applied through the disc, pad, or block. The focus then in the engineering of these abrasives is not the capacity to rub off every last bit of material, but rather to optimize the work. This focus results in smooth and even surfaces and greatly reduces scratch depth, which is an all too common byproduct of traditional sand paper.

The Siasponge products are made using two types of foams, each with their own benefits. They are EVA foams, which feature improved tear resistance and have a much softer makeup, and PU foams, which are more heat resistant and will not become wet or slippery while in contact with water.

Color Concept

When effectiveness meets convenience and efficiency, good becomes great! Siasponge has achieved this with their color-coded system to help users determine and differentiate between grit grades. If you’re looking for the coarsest grade, reach for an orange disc, pad, or block, but if you’re working on something that requires fine attention to details, look for blue or purple. Below are some common applications for each color grade.

When effectiveness meets convenience and efficiency, good becomes great! Siasponge has achieved this with their color-coded system to help users determine and differentiate between grit grades. If you’re looking for the coarsest grade, reach for an orange disc, pad, or block, but if you’re working on something that requires fine attention to details, look for blue or purple. Below are some common applications for each color grade.

Orange – Keying plastics or composites before applying primer

Yellow – Keying of primer coats prior to application or filler

Green – Fine sanding of filler in hard to reach zones

Blue – Moderate lacquer sanding

Violet – Matting of paint or varnish

In Parts II and III of our Siasponge triple feature, we’ll discuss the different abrasives products, and how, when, and where to use each of them. We’ll highlight and detail the 7970 and 7972 flat pads and discs, the 7990 and 7991 blocks, and the 7983 pads and discs. Stay tuned next week to learn more about this truly inventive line of abrasives.

For more information in the meantime, don’t hesitate to get a hold of us!

sales@chemical-concepts.com – 800.220.1966