Glass to Glass Bonding

To truly say which is the best adhesive for any application we need to know all the particulars. Including what is the environment, surface area, stress etc… But in general terms most glass to glass applications are very well met with UV curable adhesive. Providing the glass is somewhat UV transparent and you aren’t going to sink it to the bottom of the ocean for years or try to light it on fire – as I say, generally speaking. So why are UV curable adhesives so good for glass?

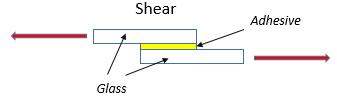

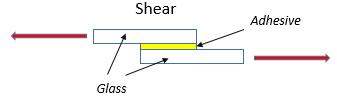

- stress absorption within the joint

- invisible bonds make for pleasing aesthetic appearance

De-bonding UV Curable adhesives is generally best done by allowing them to absorb water – hot water will work faster but check the technical data sheet for water absorption rates as some grades are quite water resistant. If you are able to get the adhesive to soften in water, de-bond before it dries out as strength will return.

Epoxies and structural acrylics also bond well to glass but the aesthetics are not as good and the process is not as fast.

UV curable adhesives allow for cure on demand which is desirable in applications where proper alignment before curing is desired. Flexible adhesives including MS Polymers and modified epoxies can also be considered for shock absorbing applications or applications that require long term severe environmental resistance.

Recommended Glass to Glass Bonding Adhesives: