LORD 202 Acrylic Adhesive – A Great Choice to Repair Marine Boat Enclosures

If you’re searching for adhesives to keep on hand in your tool kit to repair marine boat enclosures, we’ve made several recommendations in our downloadable marine product brochure.

Let’s take a moment to highlight the LORD 202 Acrylic Adhesive, one of our most popular choices for this need. Customers especially love how environmentally resistant this high-powered adhesive is, and how it withstands the tough conditions that life on the water often requires. LORD 202 adhesive provides excellent resistance to indirect UV exposure, salt spray and weathering, while resisting dilute acids, alkalis, solvents, greases, oils and moisture.

LORD® 202 acrylic adhesive, when cured with LORD Accelerator 4 or similar products, creates a fast curing adhesive system that will quickly bond a wide variety of prepared or unprepared metals and plastics. This acrylic adhesive, in combination with the recommended accelerator, replaces welding, brazing, riveting and other mechanical fastening methods.

LORD® 202 acrylic adhesive, when cured with LORD Accelerator 4 or similar products, creates a fast curing adhesive system that will quickly bond a wide variety of prepared or unprepared metals and plastics. This acrylic adhesive, in combination with the recommended accelerator, replaces welding, brazing, riveting and other mechanical fastening methods.

LORD 202 acrylic adhesive can be cured with LORD Accelerator 4, a no-mix accelerator applied to the substrate before the acrylic adhesive. (Learn more on this product below.)

Shelf Life

The shelf life for LORD 202 Acrylic Adhesive is six months when stored at temperatures under 80°F (27°C) in original, unopened container. Storage temperatures of 40-50°F (4-10°C) are recommended. If stored cold, allow product to return to room temperature before using.

A Few of the Features and Benefits You Can Expect from LORD 202 Acrylic Adhesive

Convenient – cures very quickly at room temperature.

Versatile – bonds a wide variety of substrates such as metals, ceramics and plastics; can be used with both Mix-In and No-Mix accelerators; insensitive to minor deviations from correct mix ratio.

Self-Leveling – flows into hard-to-reach places and is excellent for bonding irregular shapes.

Bonds Unprepared Metals – requires little or no substrate preparation.

Temperature Resistant – performs at a very wide range of temperatures from -40°F to +300°F (-40°C to +149°C).

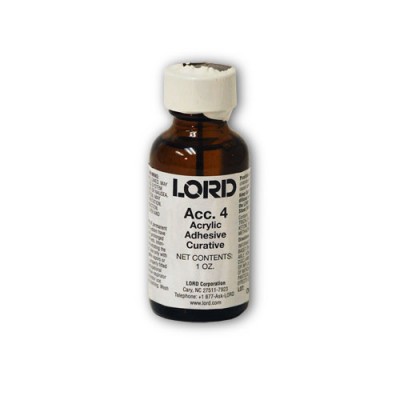

LORD® Accelerator 4 is a no-mix curative designed for use with LORD acrylic adhesives. LORD Accelerator 4 can be used with LORD 200 series, 500 series, and MaxlokTM T6 acrylic adhesives. This accelerator is available in a quart or gallon.

LORD® Accelerator 4 is a no-mix curative designed for use with LORD acrylic adhesives. LORD Accelerator 4 can be used with LORD 200 series, 500 series, and MaxlokTM T6 acrylic adhesives. This accelerator is available in a quart or gallon.

Shelf Life

The shelf life for LORD Accelerator 4 is six months when stored at 40-70°F (4-21°C) in original, unopened container. Exposure to temperatures greater than 80°F (27°C) will shorten shelf life.

A Few of the Features and Benefits You Can Expect from LORD Accelerator 4

Convenient – provides room temperature cure with all LORD acrylic adhesives.

Extended Work Time – provides extended assembly time as adhesive does not begin cure until it comes in contact with surface coated with dry accelerator.

Easy to Apply – applies easily by brush, wipe, spray or dip methods onto one or both bonding surfaces.

Fast Cure – dries in approximately one minute to an off-white crystalline film.

Environmentally Resistant – resists common environmental conditions when used with LORD acrylic adhesives.

Take a look at all of our products designed for use in the marine industry.

Do you have questions about what adhesive or related products are best for your particular need? Are you wondering what products can stand up the best harsh marine environments? Our experienced sales team will be pleased to answer any questions that you might have. Give us a call (toll-free) at 800-220-1966 or email us at sales@chemical-concepts.com. We’ll be happy to help!