Permabond’s Heat Cure Adhesive Flows like Solder

Permabond’s ES558 heat cure adhesive is like the epoxy equivalent of a soldering iron, without the hassle of all that equipment. The ES558 single-part epoxy acts like solder in that it achieves cure strength with the help of heat, whether it be from an oven, infra-red exposure, or induction heating. Typically, the hotter things get, the quicker ES558 cures. When properly heated, The ES558 flows like solder and wicks into gaps and crannies where it will cure and form a high strength and lasting bond.

Permabond’s ES558 heat cure adhesive is like the epoxy equivalent of a soldering iron, without the hassle of all that equipment. The ES558 single-part epoxy acts like solder in that it achieves cure strength with the help of heat, whether it be from an oven, infra-red exposure, or induction heating. Typically, the hotter things get, the quicker ES558 cures. When properly heated, The ES558 flows like solder and wicks into gaps and crannies where it will cure and form a high strength and lasting bond.

The Permabond ES558 is typically used as a substitute for welding and brazing joints, making it a time and labor-saving tool for welding type processes, not to mention its ability to greatly reduce the hazards often associated with this work. It’s no mystery then that it’s ideal for bonding and sealing metal components and can effectively be applied to pre-assembled joints.

Especially popular in sealing heat exchanger tubes, the ES558 provides a dependable, 100% seal between components and offers optimal stress distribution compared to traditional methods, while not taking away from a clean and sleek finish.

Advantages

- Convenient and simple – no mixing needed

- Good resistance to chemicals and high temperature resistance

- Excellent adhesive strength and resistance to vibration

- Scores favorably with shear, peel, and impact strength

Simple and Convenient

With the ability to load into a standard caulking gun, the Permabond ES558 is extremely simple to use. It’s packaged in 320 ml cartridges and requires no tedious mixing, measuring, or guessing. The adhesive can be applied at leisure, and once aligned, clamped, and heat cured, you’ve got a reliable bond! Below are the six simple steps for use.

- 1. Dispense the adhesive from the cartridge using the nozzle provided. (the nozzle can be cut according to the bead size preferred)

- 2. Apply the adhesive to a single surface and try to avoid entrapping air

- 3. Assemble parts while applying enough pressure that the adhesive is caused to spread across the entire bonding zone

- 4. Use a clamp or something similar to prevent the parts from moving during the process of curing

- 5. Be careful not to disturb the joint until it has fully cured

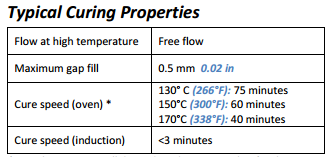

- 6. Cure with heat (see the chart below for method, temperature and time expectations)

Surfaces that can be bonded

One of the clear advantages of the ES558 is that it can effectively bond to a wide variety of substrates. However, it does have a specialty, and that specialty is metal. Below are some of the surfaces that the ES558 is best at bonding.

- Aluminum (particularly popular for heat exchanger tube sealing)

- Steel, copper and most other metals

- Tungsten carbide (ideal for wear tips, tooling etc.)

- Magnets, ferrites, ceramic materials

- Some plastics

- Composite materials

Do you have questions? Our team is always at the ready to help you with any phase of your project, whether you’re planning or finalizing. Feel free to reach out to our knowledgeable team!

sales@chemical-concepts.com – 800.220.1966