Abrasives – What are my Options?

Abrasives largely have to do with preparation, and although surface prep is a more monotonous, or dare I say ‘less exciting’ part of the application timeline, it’s just as important as the next step in the process, like adhesion. Good adhesion or finish, if you’re using lacquer or paint, is very much contingent upon how well things were cleaned up, broken down, and softened up by the abrasion at the beginning of the project -that’s why using the right abrasive product is key.

Abrasives largely have to do with preparation, and although surface prep is a more monotonous, or dare I say ‘less exciting’ part of the application timeline, it’s just as important as the next step in the process, like adhesion. Good adhesion or finish, if you’re using lacquer or paint, is very much contingent upon how well things were cleaned up, broken down, and softened up by the abrasion at the beginning of the project -that’s why using the right abrasive product is key.

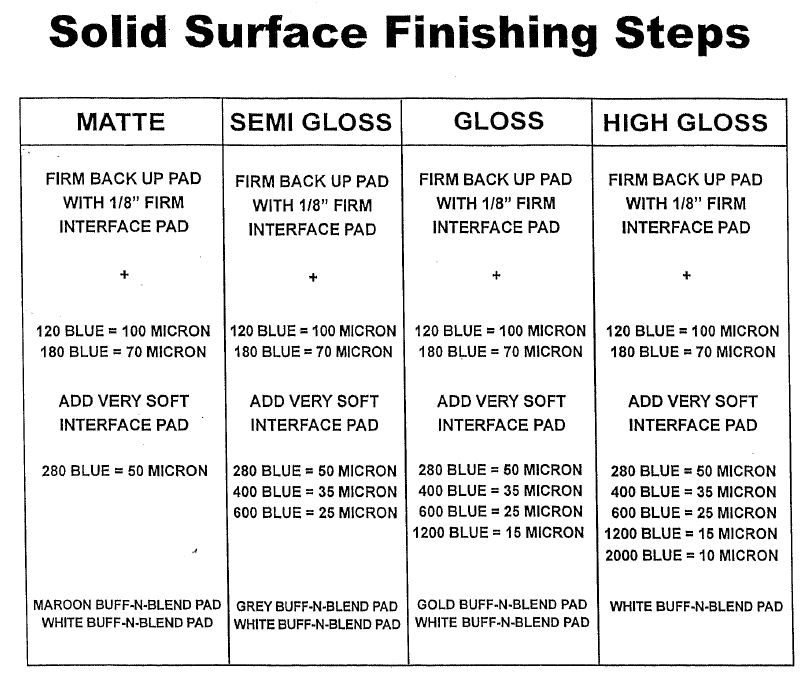

Sia Abrasives is a world leader in abrasive systems and we at Chemical Concepts proudly distribute and recommend them. We’ll use their products as a model and rule of thumb to examine the types of abrasives and where they should be used. Below is a helpful solid surface finishing steps guide for reference. Click on it to make it larger.

Types of abrasives

Coated Abrasives – Coated abrasives are flexible substrates that are bonded to an abrasive grain material by way of adhesion. They can be paper, cloth or plastic and come in ranges of grit size, from very coarse to ultrafine. These abrasives typically come in discs, squares or belts, and are a conventional and multi-faceted choice for your abrasion project. Coated abrasives are traditionally used on metal, wood and composite surfaces.

Nonwoven Abrasives – Nonwoven abrasives are a bit less conventional than their coated counterparts, being leveraged mainly in industrial, mass production processes. They’re made typically out of a polyamide fiber with resin and abrasive grit, and come in discs, strips, rolls, belts and squares. Nonwoven abrasives can adapt well to contours, can be utilized in wet or dry conditions, and their structure greatly limits clogging with industrial machinery.

Foam Abrasives – Foam adhesives are probably the best choice if you’re preparing and/or sanding a profiled surface, like top grade wood. Foam varieties are also advantageous for hard to reach areas because of their ability to conform and avoid creasing, even if they’re folded or bent. Foam adhesives are great at achieving a detailed, scratch-free, and homogenous surface. Foam adhesives usually come in discs, squares and bars.

Bonded Abrasives – Bonded abrasives are by far the most specialized abrasives, almost always coming in discs and many times having very specific characteristics. Grit type, like aluminum oxide or silicone carbide, for instance, is one of the several variables involved with bonded abrasives. Hardness, grit size, disc format, bonding type, and disc speed characteristics are other variables for this type of adhesive, leveraged mainly with precise cutting and grinding.

The SIACAR 1940 5” No hole – This is a great general purpose, coated adhesive from Sia used to condition surfaces ahead of the treatment of body filler, primer filler, lacquer or paint. The 1940 also has a good lifetime, a homogenous sanding pattern, and has a grit range of 40- 1500.

Contact our team if you’re not sure what size or grit type is ideal for your application or your tool(s). We’re happy to help. In fact, it’s why our customers tend to “stick with us!”

sales@chemical-concepts.com 800.220.1966