Description

Pyrosil® is a proprietary flame technology from SURA Instruments in Germany, which has a 30+ year track record of success in pre-treating and adhesion promotion for many low-energy substrates such as HDPE, PP, PE, Nylon, Glass, Plastic, Porcelain, and Metal. Pyrosil® is much more than standard flame treatment – because flame treatment can not permanently solve adhesion problems. Pyrosil® chemically changes surface structures and actually increases adhesion for up to 24 hours allowing you to drastically increase the bond strength of adhesives that would not typically work well.

Pyrosil® GVE2 HB is a portable tabletop unit used for the flame treatment surface silicate coating tool using the principle of flame pyrolysis. It burns a gas mix of (propane and butane) and PYROSIL®, consisting of silicon-organic compounds, in the flame, forming several a nanometer thin but very dense and tightly adhesive silicone Si0²- layer on metal, glass, ceramics, and plastics.

Additional Pyrosil Flame Systems

- FB25 Handheld Kit

- Semi-Automatic Units*

- Automatic Units*

*For Semi-Automatic and Automatic Units Contact Chemical Concepts if interested!

Benefits

- Extended Adhesion Time: Up to 24 hours, compared to 10-15 minutes with standard flame treatment.

- Improved Strength: Increased torque, shear, and peel strength for more reliable bonding.

- Cost-Effective Savings: Allows the use of non-specialized, affordable adhesives, expanding bonding options for various substrates.

- Increased Durability: Improved adhesion against physical, mechanical, and chemical wear

Applications:

- Increasing the shear strength of adhesives used in manufacturing

- Increasing the bonding of silicones used in architectural applications

- Improving the durability of of hydrophilic coatings used on solar panels

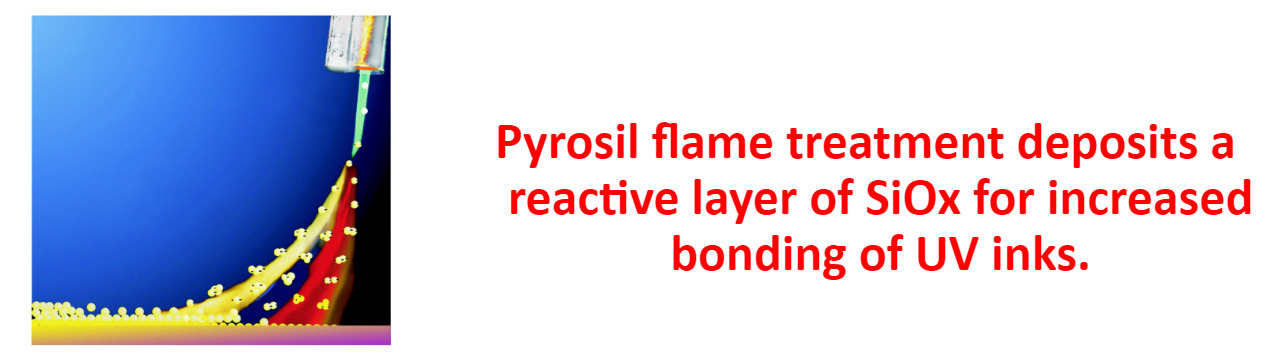

How Pyrosil Works:

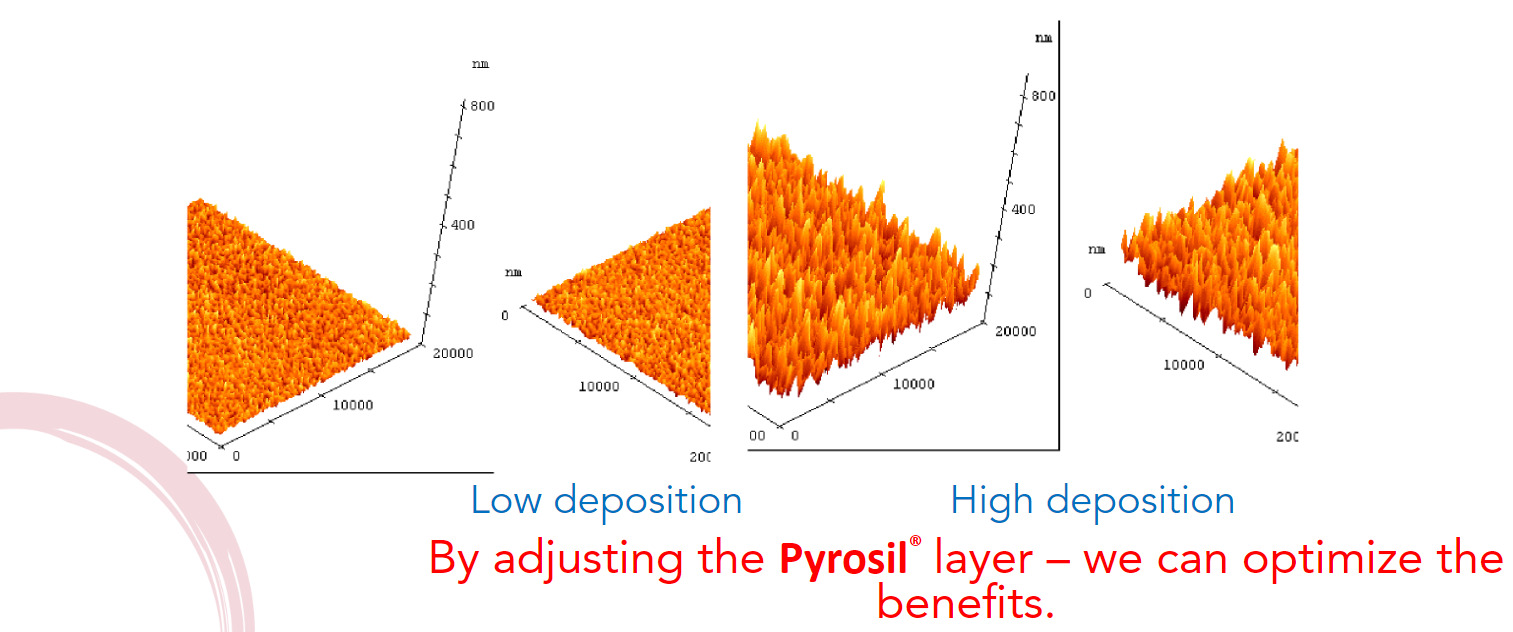

- Pyrosil flame treatment deposits a reactive layer of SiOx for increased bonding of adhesives and UV inks

- After treating the surface you will increase the surface tension of the substrate for improved hydrophilicity (wettability) resulting in improved adhesion, durability, and scratch resistance of adhesives, coatings, silicones, UV inks, paints and other surface treatments

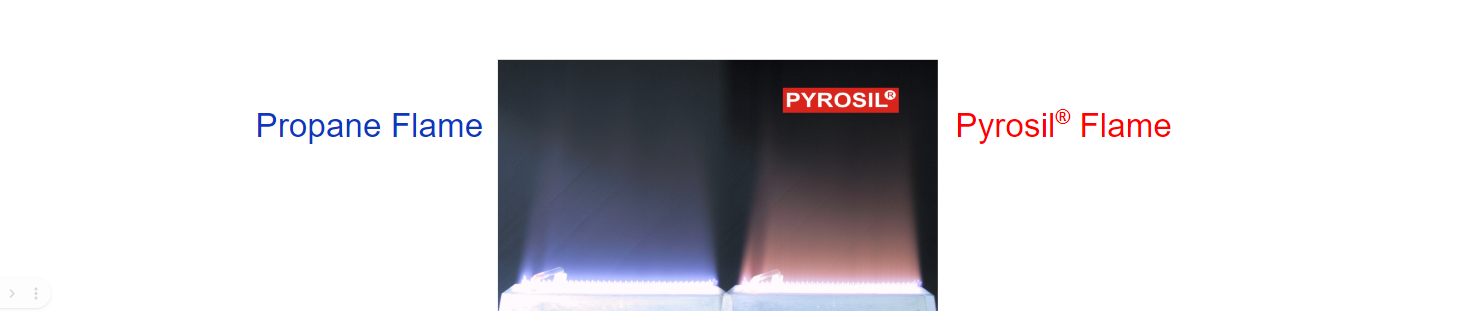

Standard Flame Treatment vs. Pyrosil Flame Treatment

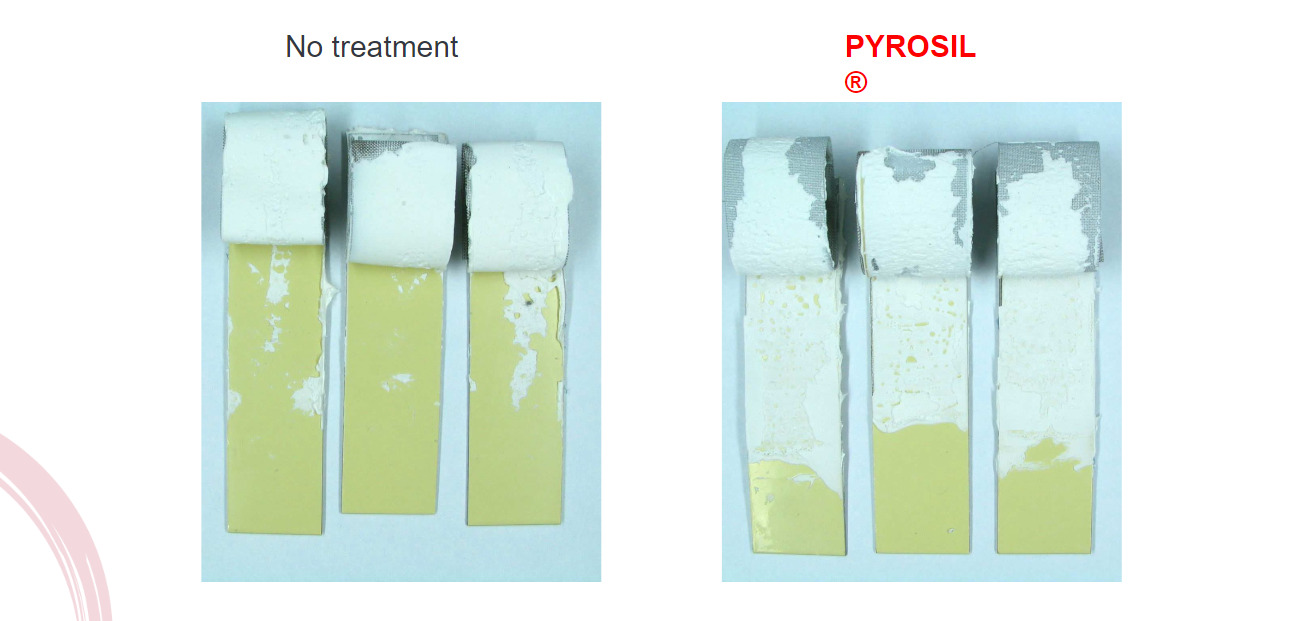

Testing Adhesion of Silicones on Powdercoatings:

Reviews

There are no reviews yet.